We’re asked all the time if we can mold different polymer types from the exact same mold. However, the answer may vary because it is dependent upon how much rubber formulation is shifting.

For instance, if we’re going from a 70 Shore A durometer EPDM chemical to some 60 durometer EPDM compound, there typically won’t be much change in the shrink rate. It ought to fall within the tolerance selection of the finished part.

In case the customer now wants to form a 30 durometer silicone rubber compound, there might be a substantial difference in the dimensions of the finished part, either smaller or larger than tolerance allows. If the tolerance range can grow, then there is a reasonable probability that the mold and part will work.

Purchasing agents and engineers must work together to figure out what would be acceptable. Opening tolerance can stop an increase in the cost of constructing new tooling and eligibility for a deviation of the slight tolerance range.

Compounding Factors Which Contribute to Shrink Rate

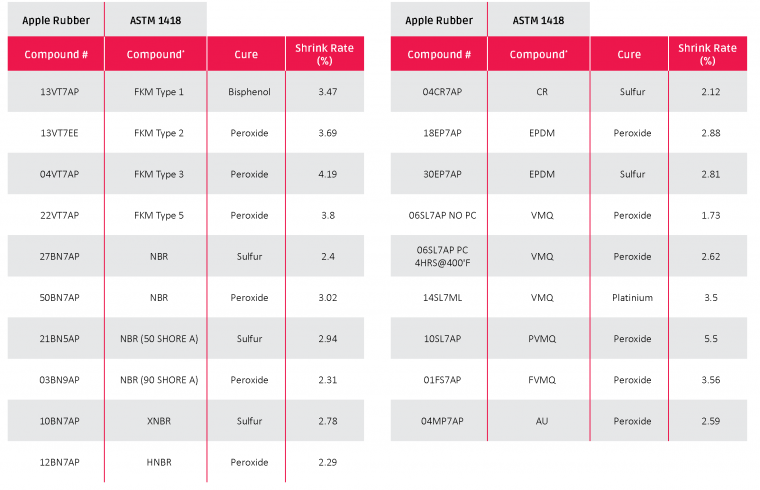

Heal kinds : Sulfur and peroxide remedies may have very substantial shrink rates. We have seen peroxide cured formulation have a greater shrink rate. A sulfur cured NBR may have a 2.4% psychologist speed, while a peroxide cured might possess a 3.02 percent.

Polymer Type: Silicones and FKM compounds usually have a greater psychologist speed than nitrile or EPDM chemicals.

Durometer: Softer durometers typically have a greater shrink rate than tougher durometers.

Processing Factors Which Contribute to Shrink Rate

Injection Pressure: Greater injection pressure may cause a higher shrink rate.

Pack Pressure: The psychologist rate of plastic could be changed more than thermoset rubber compounds. Higher pack pressures may still alter the finished dimensions slightly.